Types Of Mechanical Transmission Systems

Most mechanical transmission fall in three basic categories with three elements each, namely-

(1) Clutch, Gearbox and Live Axle,

(2) Clutch, Gearbox and Dead Axle,

(3) Clutch, Gearbox and Axle-less transmission

Clutch, Gearbox and Live Axle -->

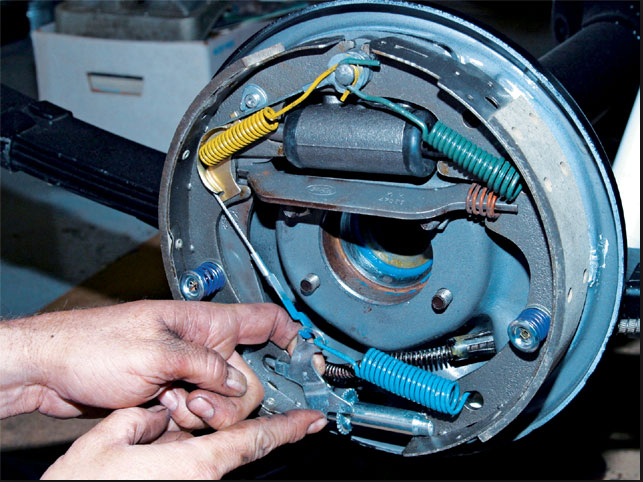

The engine is in the front with its crankshaft parallel to the axis of vehicle.The drive is transmitted from engine through a clutch and a short shaft 'c' to the gearbox ('c' is almost always integral with the primary gear in gearbox, but sometimes is a separate component with universal joints).From the gearbox the "Propeller Shaft"-having U joints at both ends and a sliding joint at front end-takes the drive to rear live axle.Live axle is the one through which the drive is transmitted while a dead axle is the one through which the drive is not transmitted.Bevel or worm gearing (g) within the axle turns the drive through 90°, and differential gears divide it equally between the two drive shafts, or half-shafts ( j), which take it out to the wheels.

The function of clutch is to engage or disengage engine from wheels smoothly without any shocks.

The principal function of the gearbox is to enable the driver to change the leverage between the engine and driving wheels to suit the prevailing conditions– gradient, load, speed required, etc.

As the propeller shaft transmits the drive on to the back axle, the universal joints at its ends allow both the engine-and-gearbox assembly and the back axle to move relative to one

Gearing (g), in what is called the final drive unit, turns the drive through 90° and reduces the speed in a ratio of about 4 : 1, since the driving wheels must

Live axles are built in several forms. That in Fig. is called a single-reduction axle, because the reduction in speed between the propeller shaft and final drive is effected in one stage, in the final drive at (g). In some heavy trucks, because the reduction ratio may have to be much higher, this reduction

Transmission Requirements

In the next post--"Rear Engine Vehicles with Live Axle".

(1) Clutch, Gearbox and Live Axle,

(2) Clutch, Gearbox and Dead Axle,

(3) Clutch, Gearbox and Axle-less transmission

Clutch, Gearbox and Live Axle -->

The function of clutch is to engage or disengage engine from wheels smoothly without any shocks.

The principal function of the gearbox is to enable the driver to change the leverage between the engine and driving wheels to suit the prevailing conditions– gradient, load, speed required, etc.

As the propeller shaft transmits the drive on to the back axle, the universal joints at its ends allow both the engine-and-gearbox assembly and the back axle to move relative to one

another, as their spring elements deflect. The sliding joint, usually integral

with one of the universal joints, accommodates variations in length of the

propeller shaft as its rear end rises and falls vertically with the back axle and

its front end pivots about the universal joint just behind the gearbox.

Gearing (g), in what is called the final drive unit, turns the drive through 90° and reduces the speed in a ratio of about 4 : 1, since the driving wheels must

rotate much more slowly than the engine. Within the final drive unit too is

the differential gearing, which shares the driving torque equally between the

two road wheels while allowing them, nevertheless, to rotate simultaneously

at different speeds while the vehicle is cornering.

Live axles are built in several forms. That in Fig. is called a single-reduction axle, because the reduction in speed between the propeller shaft and final drive is effected in one stage, in the final drive at (g). In some heavy trucks, because the reduction ratio may have to be much higher, this reduction

is done in two or even three stages, a double- or even triple-reduction axle

being used.

Transmission Requirements

In the next post--"Rear Engine Vehicles with Live Axle".

Hey Nice Blog!!! Thank you for sharing information. Wonderful blog & good post.Its really helpful for me, waiting for a more new post. Keep Blogging! Working tool supplier

ReplyDelete