Drum Brakes

DRUM BRAKE

PRINCIPLE OF OPERATION-

DRUM BRAKE COMPONENTS-

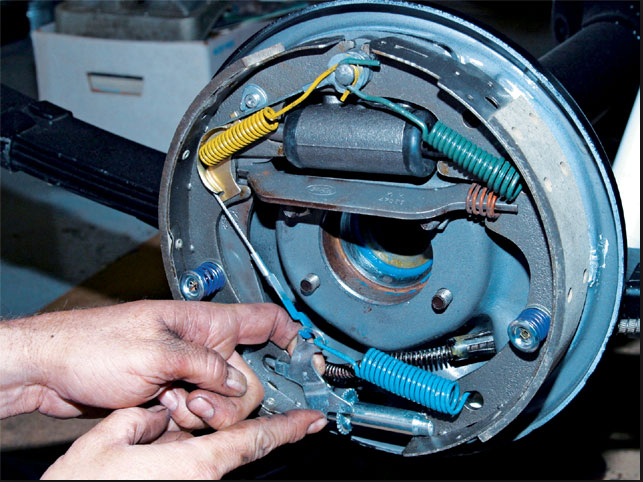

Modern drum brakes are sometimes called internal expanding brakes, since the brake components are internal (inside a drum), and the shoes must expand, or move outward, to contact the drum. Drum brake components vary only slightly between manufacturers. Most design differences are in the methods of brake shoe anchoring and spring placement.

Backing Plate -

To provide a foundation for the drum brake COMPONENTS and to act as a splash shield against water and road debris, a backing plate (sometimes call ed a support plate) is used. The wheel cylinder,brake shoes, and springs are attached to the backing plate.The flat spots on the backing plate are cal led support pads. The wheel cylinder is usually solidly attached to the top of the backing plate. Most wheel cylinders are bolted to the backing plate.

Most backing plates are discs of stamped steel, bolted or riveted to the spindle assembly on front brakes and to the axle flange on rear brakes.A few backing plates are made of aluminum or plastic. These plates are used primarily as splash shields with the wheel cylinder and anchors mounted on a steel support plate.

ANCHORS-

Anchors, which are solid attaching points for the brake shoes and springs, are also installed on the backing

plate. Anchors are often called anchor pins or anchor plates, depending on their construction. Some anchors support only the shoes, whiIe others are connecting points for the shoes and return springs.

Brake Shoe Assembly-

brake shoe assemblies consist of two major parts, the steel shoe, and the friction material lining. The steel brake shoe holds and supports the brake lining. Wheel cylinder movement is transmitted to the lining by the shoe. The two parts of a brake shoe are the table and web. They may be welded together or stamped from a single piece of steel. The table and web vary in thickness and the web mayor may not be reinforced.

Nibs and Support Pads-

Some shoes have raised spots on the table which contact raised spots on the backing plate when the shoe is

installed. These are called nibs. The nibs and support pads provide a bearing surface for the shoe to slide on. Some shoes do not have nibs and the edge of the shoe table slides on the backing plate support pads.

Primary and Secondary Shoes-

There are two types of brake shoes in every drum brake assembly. The leading or primary shoe faces the

front of the vehicle, and the trailing or secondary shoe faces the rear of the vehicle. Since the secondary shoe performs more of the braking effort, the primary shoe is often smaller.

Linings -

The brake lining is the friction material which contacts the drum. Brake linings must be able to produce friction in order to properly stop the vehicle. Some of these factors are the ability to stop well in cold and wet weather, and resistance to compression and swelling when hot. The lining should not fade under normal braking conditions.

Lining Size and Attachment -

Brake lining thickness and surface area varies with vehicle size and anticipated demands. Older vehicles with

front drum brakes have linings with a large surface area for more braking power. These linings are relatively thin to reduce heat buildup. Smaller brake shoes are used on the rear. On modern front- and rear-wheel drive vehicles, the rear brake linings have a smaller surface area, since they carry a smaller portion of the braking load. These linings are relatively thick for longer wear. To perform their job, the brake linings must be securely attached to the shoe table. They must also be attached tightly enough to allow heat transfer between the lining and the shoe. The brake lining is attached to the shoe table in one of two ways.

1. Some linings are attached with rivets. The rivets are usually made of brass or copper to reduce drum damage .Some rivets are tubular, with a hole in the center. This allows brake dust to exit the pad and drum surface.

1. Some linings are attached with rivets. The rivets are usually made of brass or copper to reduce drum damage .Some rivets are tubular, with a hole in the center. This allows brake dust to exit the pad and drum surface.

2.Other linings are attached by bonding. Bonding is a method of gluing the lining to the shoe table by pressure and heat. A high temperature cement is placed on the back of the lining. Then the lining is tightly held against the shoe table as heat is applied. This creates a tight bond, securely holding the two pieces together.

lining contact method-

Lining-to-drum contact is very important for proper brake function in any given design.The contact can be

designed by arc grinding the shoes. Arc grinding is actually a sanding process done at the factory which removes small amounts of the lining's top layer until it has the proper curve. so that at the time of braking the line is in full contact with the drum and The contour lining is thicker at the center. When the brakes are first applied and the lining moves into contact with the drum, the thicker center section contacts the drum first.

and there is a clearance of about 0.25 mm between lining and drum.

ReplyDeleteGreat Article… I love to read your articles because your writing style is too good, it is very very helpful for all of us and I never get bored while reading your article because they are becomes more and more interesting from the starting lines until the end.

Brake Lining Adhesive Suppliers

Thank you so much for this nice information. Hope so many people will get aware of this and useful as well. And please keep update like this. brake lining adhesive suppliers

ReplyDeleteVery Informative.. Hope all will get the clear idea about Drum Brake Brake Lining

ReplyDeleteDrum Brake Brake Lining

Very Informative.. Hope all will get the clear idea about Drum Brake Brake Lining

ReplyDeleteDrum Brake Brake Lining

Wow it is really wonderful and awesome thus it is very much useful for me to understand many concepts and helped me a lot. it is really explainable very well and i got more information from your blog brake lining adhesive suppliers

ReplyDeleteIt was so interesting to read, really you provide good information.

ReplyDeleteBrake Lining

Really I feel happy to see this useful blog, Thanks for sharing such a nice blog.

ReplyDeleteBrake Lining Adhesive Suppliers

Nice Post. Thanks for Sharing

ReplyDeleteAutomobile Part Manufacturers

Automobile Spare Part Manufacturers

Machinery Manufacturers

Filter Manufacturers

Brake Manufacturers

Gear Manufacturers

Shock Absorber Manufacturers

Universal Joint Cross Manufacturers

Bearing Manufacturers

Brake Shoe Manufacturers

good

ReplyDelete